MOBILE:13705419876

FAX:0531-83262123

CONTACTS:Manager Yang

ADDRESS: Zheshan Industrial Park, Zhangqiu District, Jinan City, Shandong Province, China

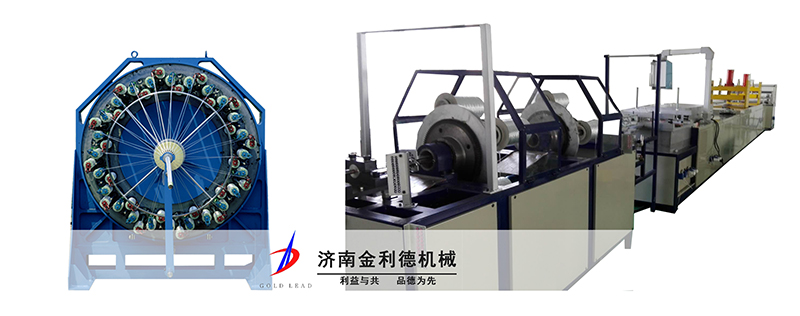

The machine consists of knitting, winding and pultrusion three systems. The whole production line has the advantage of continuous production, low labor cost and higher impact strength than fiber winding because fiberglass is staggered placed.

Applicable Raw Materials:

Fiberglass, Epoxy Resin and UPR

Main Technical Specification:

Horizontal Type High Speed Knitting Machine

No. of bobbins

120

Diameter of horngear

130mm

Knitting method

Horizontal type

Rotation speed of horngear

180rpm

Bobbin speed

6rpm (adjustable)

Knitting diameter

100-160mm

Knitting pitch

100-600

Motor Power

5kW×4 (servo motor)

Dimension

2980×2980

Winding system technical specification

Technical parameter

Model

BLR-2-75

BLR-2-200

BLR-4-75

BLR-4-200

No. of pullwinding fiberglass layers

4

4

7

7

No. of winding heads

2

2

4

4

Winding rotation speed

5-130r.p.m

5-50r.p.m

5-130r.p.m

5-50r.p.m

Roller diameter

270mm

270mm

270mm

270mm

No. of rollers

4

16

8

32

Winding diameter

75mm

200mm

75mm

200mm

No. of resin baths

3

3

5

5

Traction speed

5-70cm/min

5-70cm/min

5-70cm/min

5-70cm/min

Pultrusion system technical specification:

Technical Data

Pulling force

200kN/300kN

Power

2×3kW

Clamping mode

Hydraulic cylinder

Max. Clamping envelope

800×300mm (can be customer-made)

Pulling speed

0.1-0.8m/min

Number of heating zones

4 (can be customer-made)

Pulling operation mehod

Manual/Auto, adjustable

Clamping length of die table

900mm (can be customer-made)

Copyright © 2013-2018 wayboo.cn. All Rights Reserved. Zheshan Industrial Park, Zhangqiu District, Jinan City, Shandong Province, China 鲁ICP备11031456号-3