MOBILE:13705419876

FAX:0531-83262123

CONTACTS:Manager Yang

ADDRESS: Zheshan Industrial Park, Zhangqiu District, Jinan City, Shandong Province, China

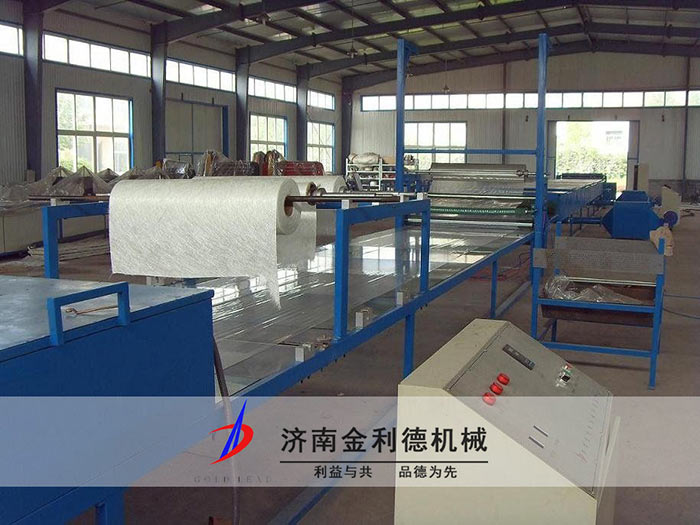

FRP Sheet Production Line

The resin and fiberglass (yarn or roving) are put on the lower film (resin bath ). Across the proportional pump, the resin, accelerant and curing agent go into mixer after accurate measurement. After uniform mixing, the resin drops onto the tension lower film and then forms resin bed. The putting number of the resin can be controlled by adjustable scraper. Chopped mat is laid over the resin bed and be dipped, then the dipping process is accelerated by a heating area (optional). The upper layer lays a aging proof film, thus formed a sandwich area between fiberglass and resin bed, its thickness can be controlled.

Characteristics:

As the operating crafts, the proportional pump can be adjusted, and the raw materials can be matched automatically.

The temperature of the resin bath can be adjusted automatically or manually, thus can meet the producing need.

The temperature of every section of the furnace can be adjusted automatically or manually. By adjusting electric heater and exhaust fan, it can meet the production requirements.

Traction speed can be adjusted according to the crafts.

Cutting speed can be adjusted to suit the producing speed.

The line can be operated by automatic control system or manual control to ensure the regular production.

Technical Parameter

1. Dimension ≈60m×4m×3.5m (length×width×height)

2. Max traction speed 5m/min (thickness≦1mm)

3. Total installed power ≈60KW

4. Product specifications

Thickness 0.6mm~4mm

Width 1600mm (sheet)

Corrugated height max 130mm

Length infinite

5. Product yield: 95%, type: translucent type, semi-translucent type, burning-proof type, and common type , transmittance: 80~86% (sheet thickness 0.8mm)

6. Fiberglass contents 25%~40%

Main parts supplier:

Copyright © 2013-2018 wayboo.cn. All Rights Reserved. Zheshan Industrial Park, Zhangqiu District, Jinan City, Shandong Province, China 鲁ICP备11031456号-3